Control jigs

for assembly

A3S Mécanique designs and manufactures custom industrial assembly control jigs to optimize your welding, assembly, cutting, and quality control operations.

Our jigs are designed to deliver precision, time savings, ergonomics, and safety on your production lines.

With our in-house design office, we support you from needs analysis to the delivery of ready-to-use solutions, tailored to your production rates, tolerances, and technical constraints.

Discover below the different types of jigs we offer, through several concrete examples of completed projects.

Our welding jigs are designed to ensure rigid and precise holding of parts during the welding process.

They allow you to:

-

Limit thermal deformation,

-

Reduce rework and touch-ups,

-

Improve weld quality,

-

Shorten setup times.

We build jigs for tubular structures, welded frames, and steel/stainless steel or aluminum assemblies.

Our solutions are adapted to the specific constraints of your parts and your workshop organization.

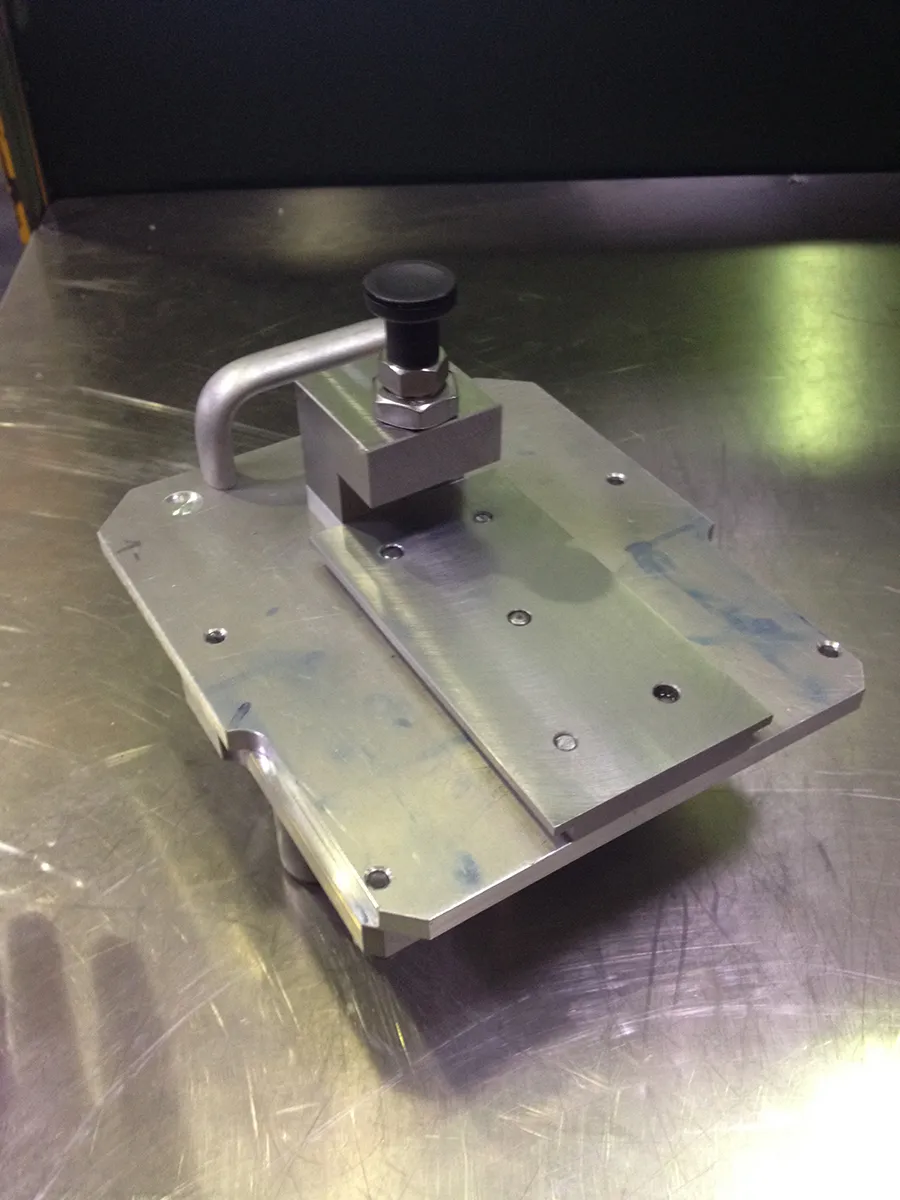

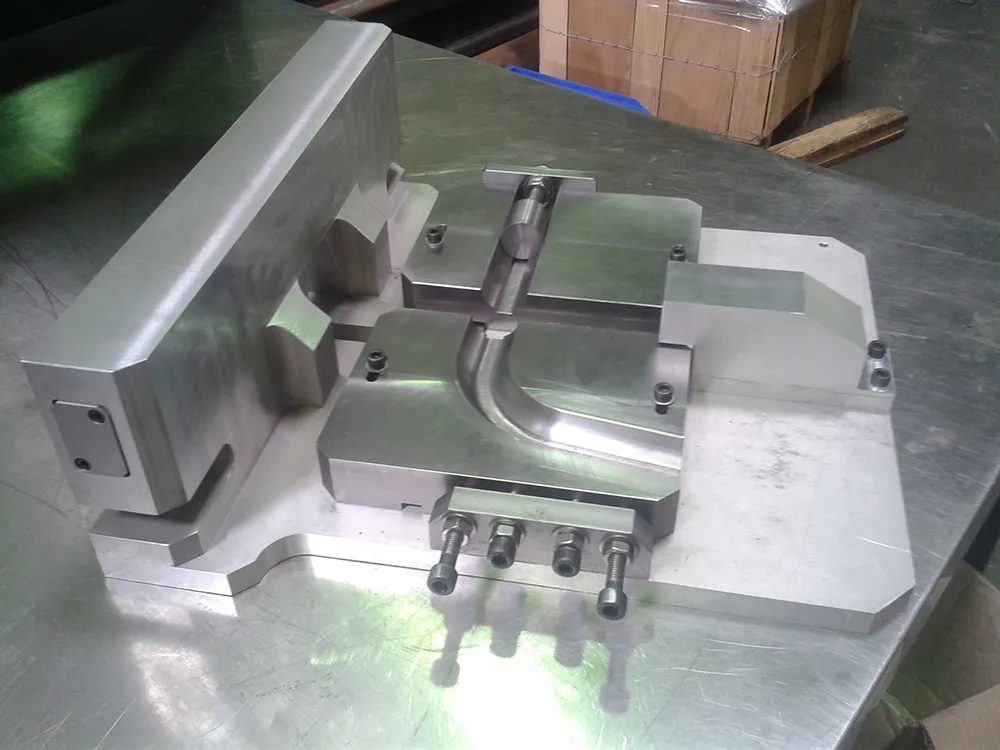

Assembly jigs make it easier to achieve precise positioning and alignment of parts to be assembled, whether by welding, screwing, or gluing.

Their purpose:

-

Reduce human error,

-

Speed up repetitive tasks,

-

Ensure perfect repeatability,

-

Improve overall productivity.

They are especially useful in sectors such as agri-equipment, industrial sheet metal, and special-purpose machinery.

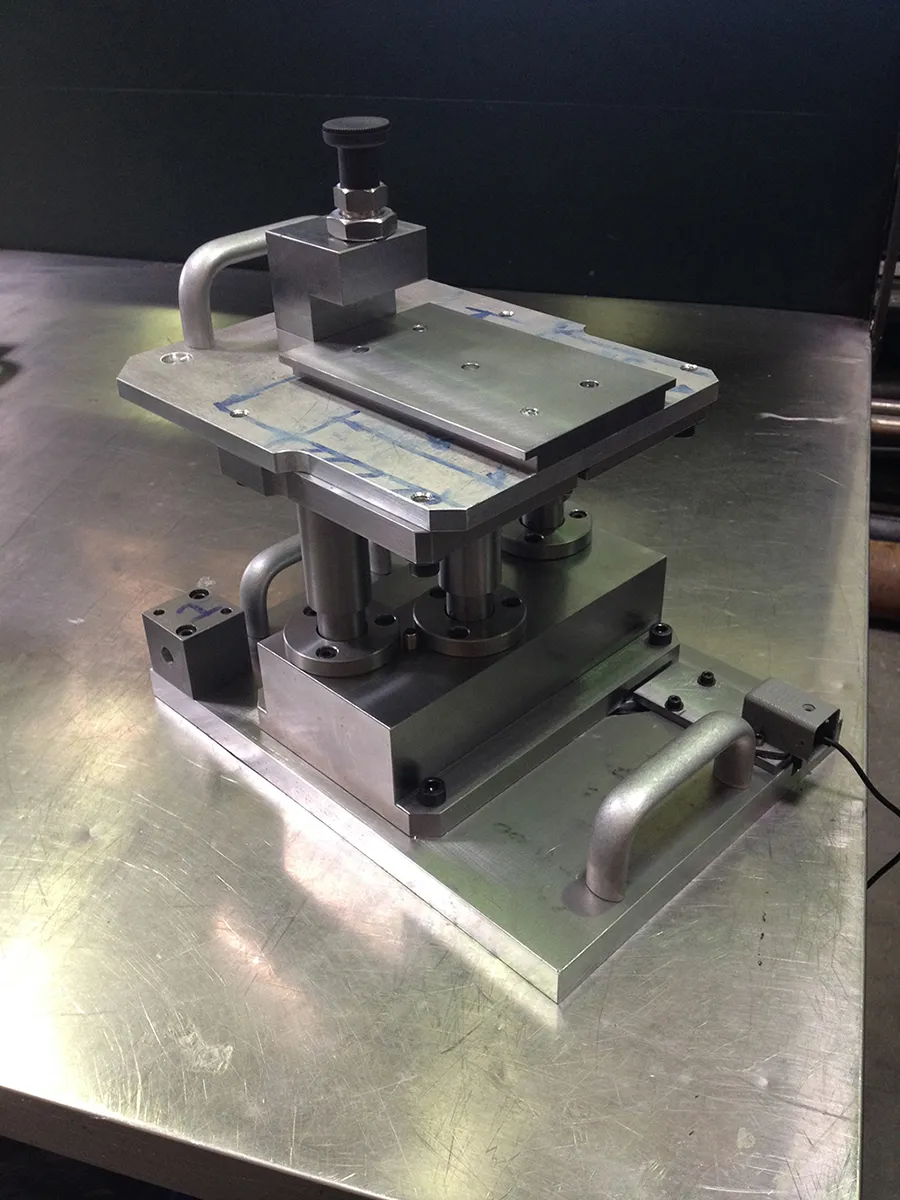

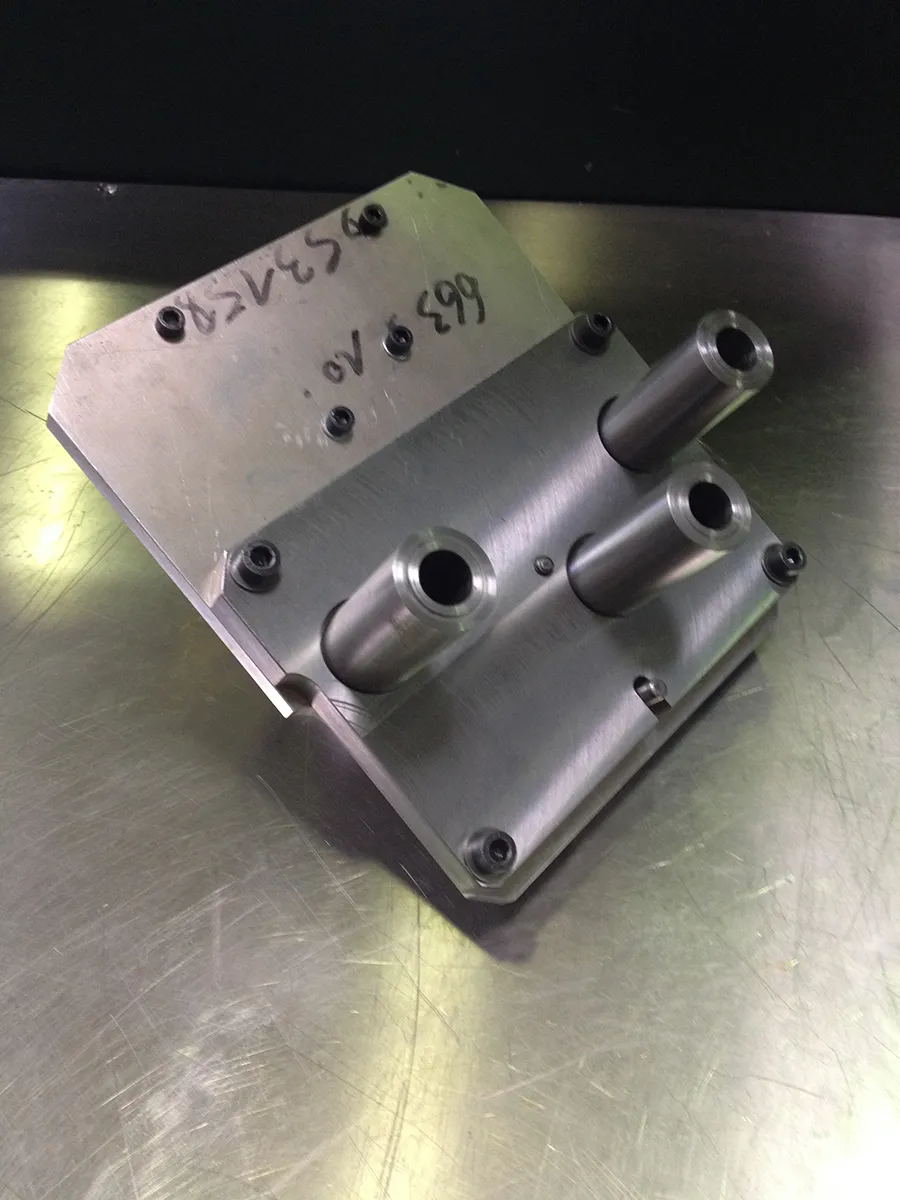

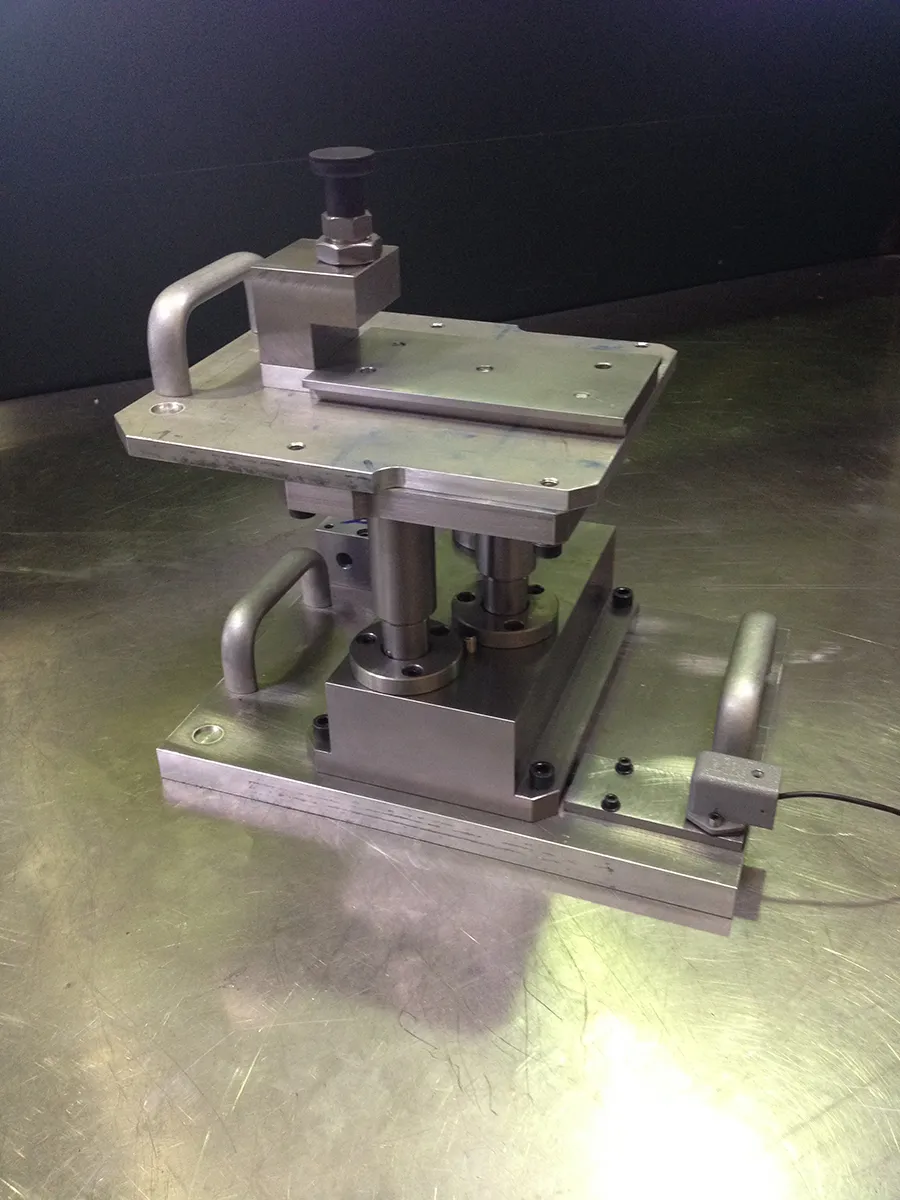

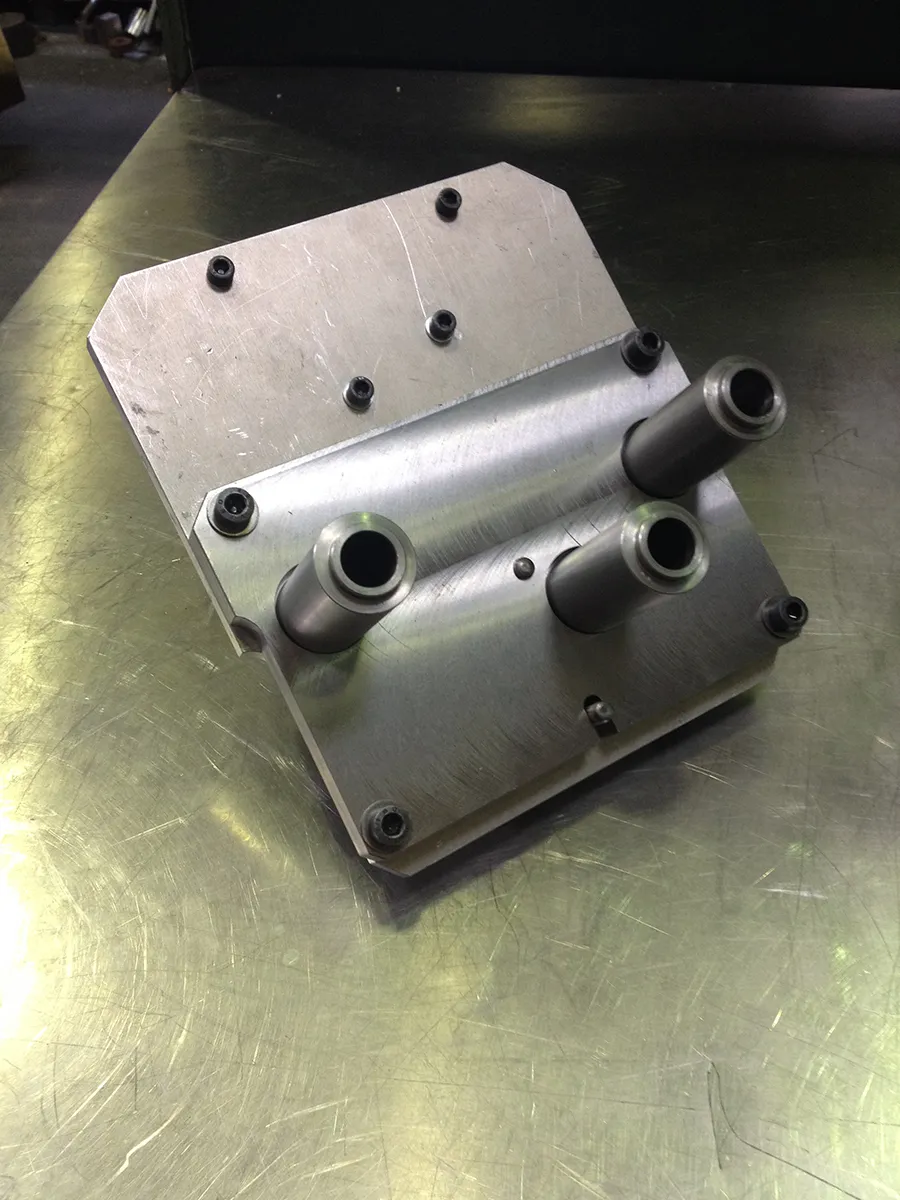

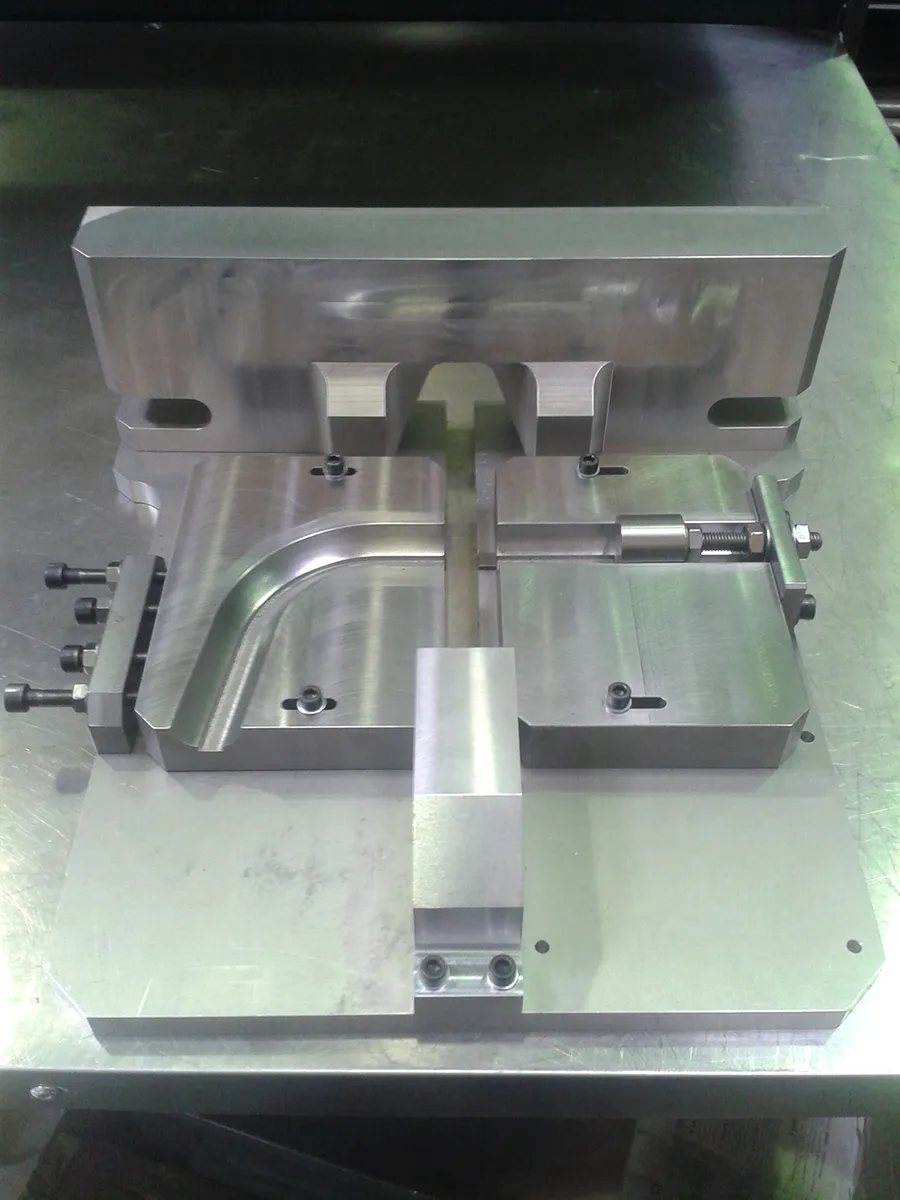

Control jigs allow for quick and simple verification of a part’s geometric or dimensional conformity.

Used at the beginning, during, or at the end of production, they help to:

-

Immediately detect non-conformities,

-

Reduce inspection times,

-

Avoid the use of expensive and complex measuring tools.

We also build combined jigs that allow both assembly and inspection on the same base.

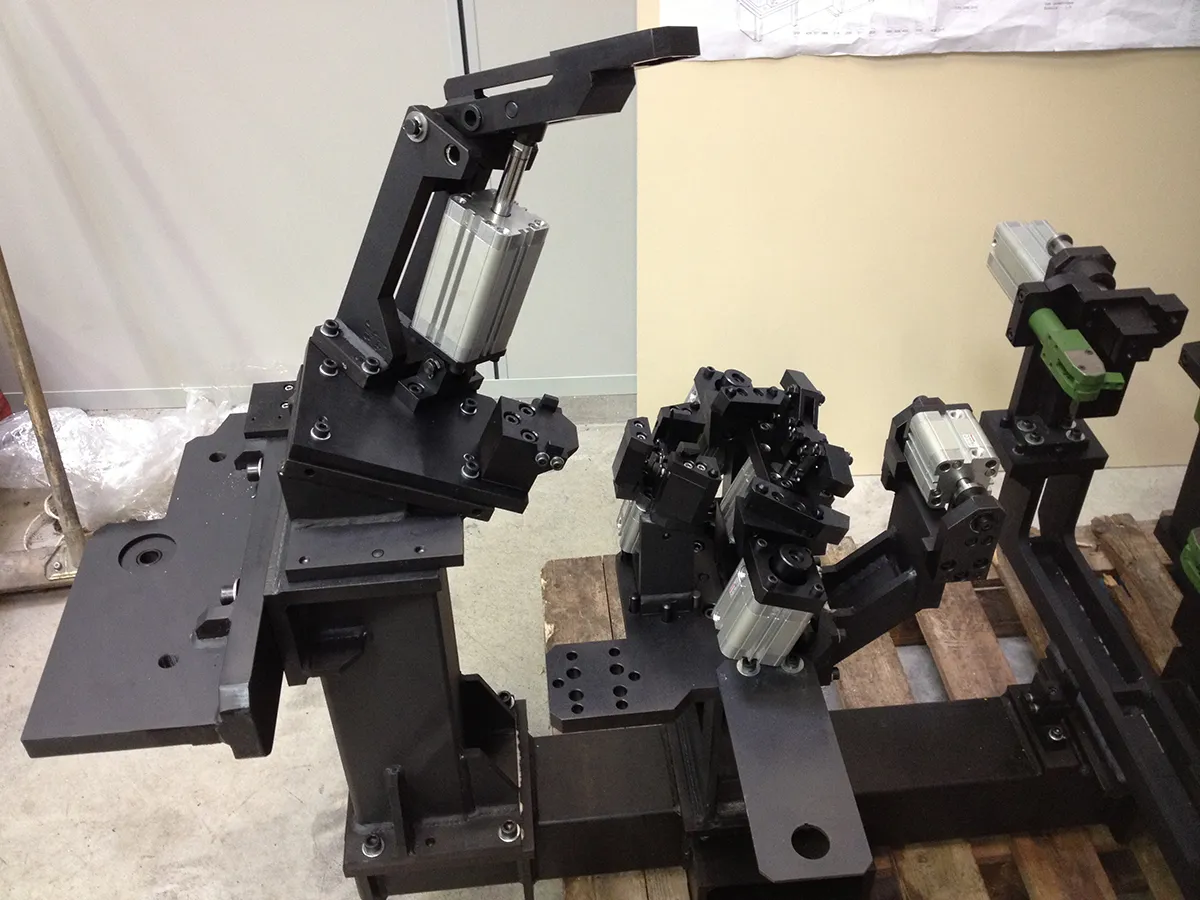

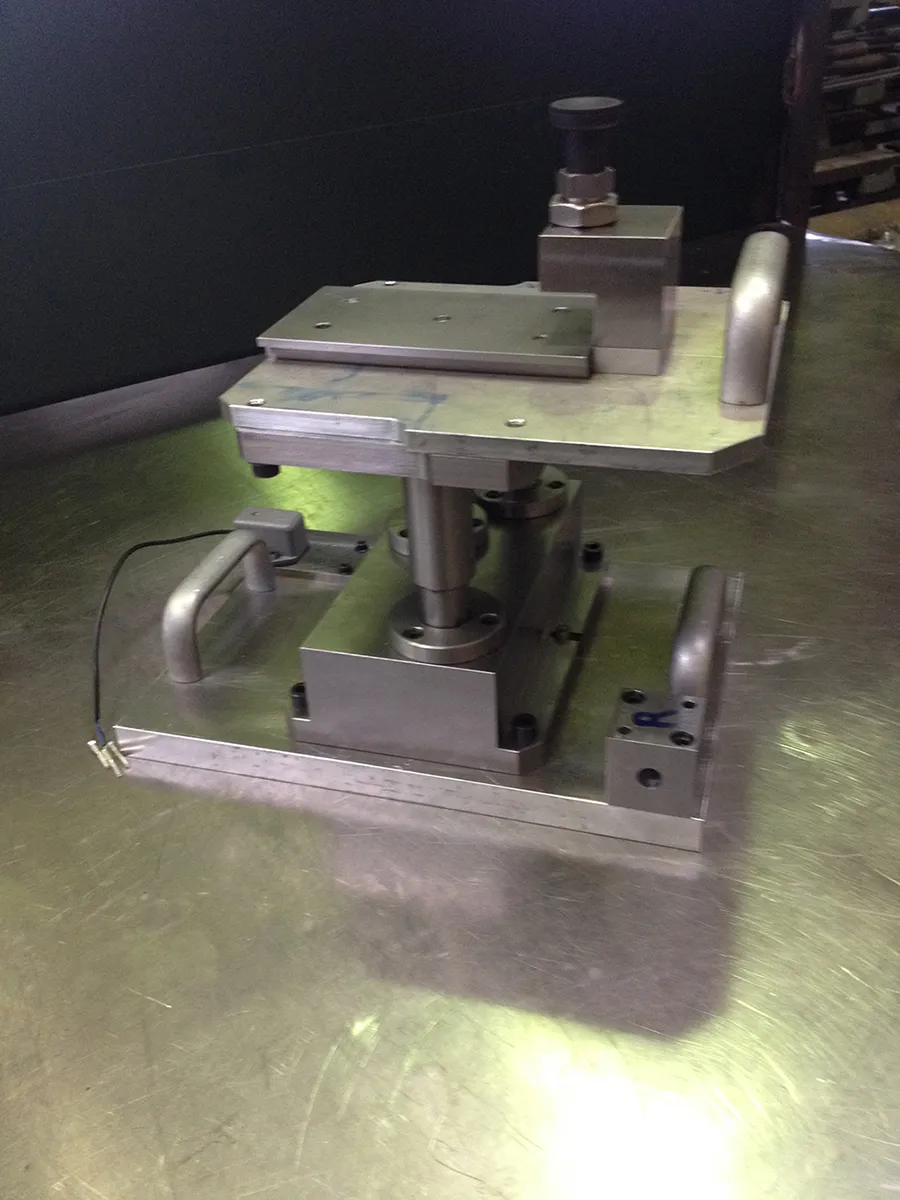

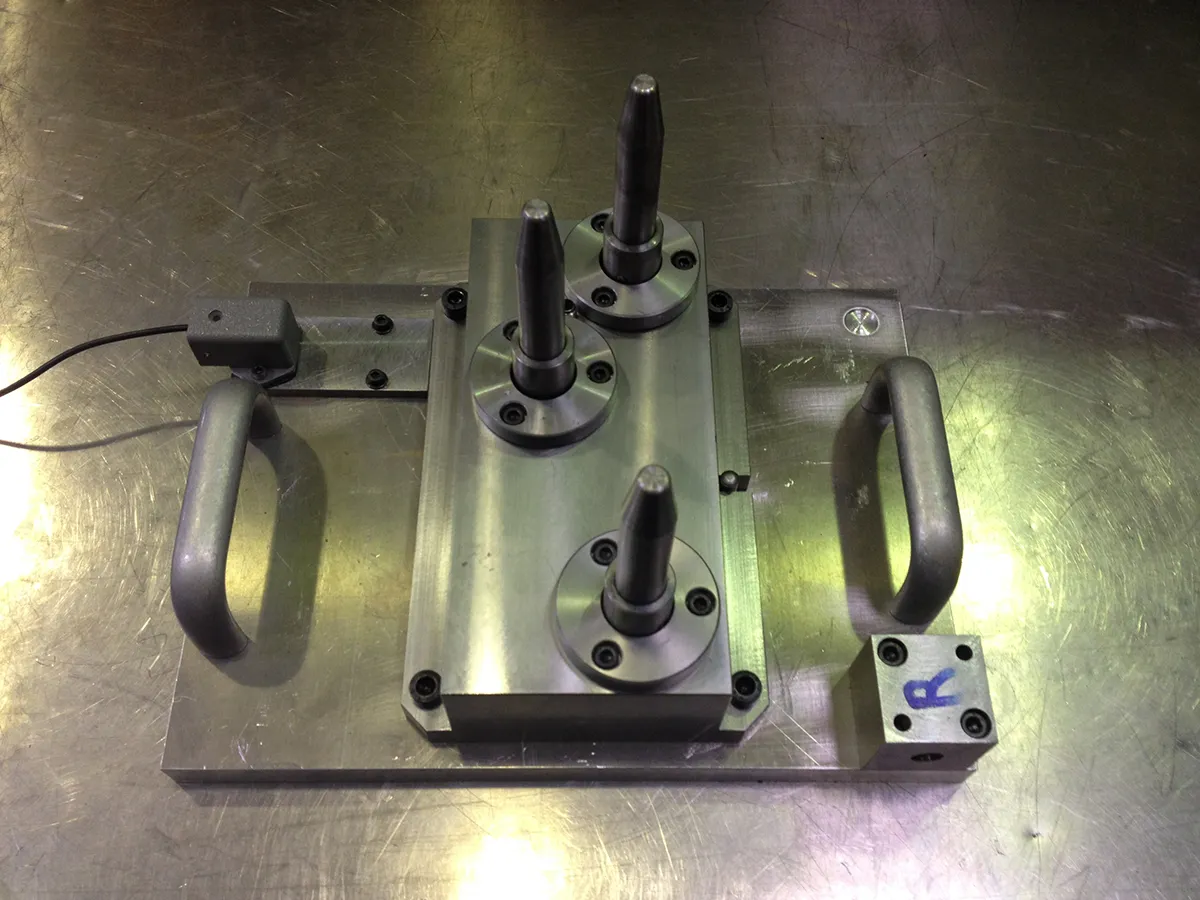

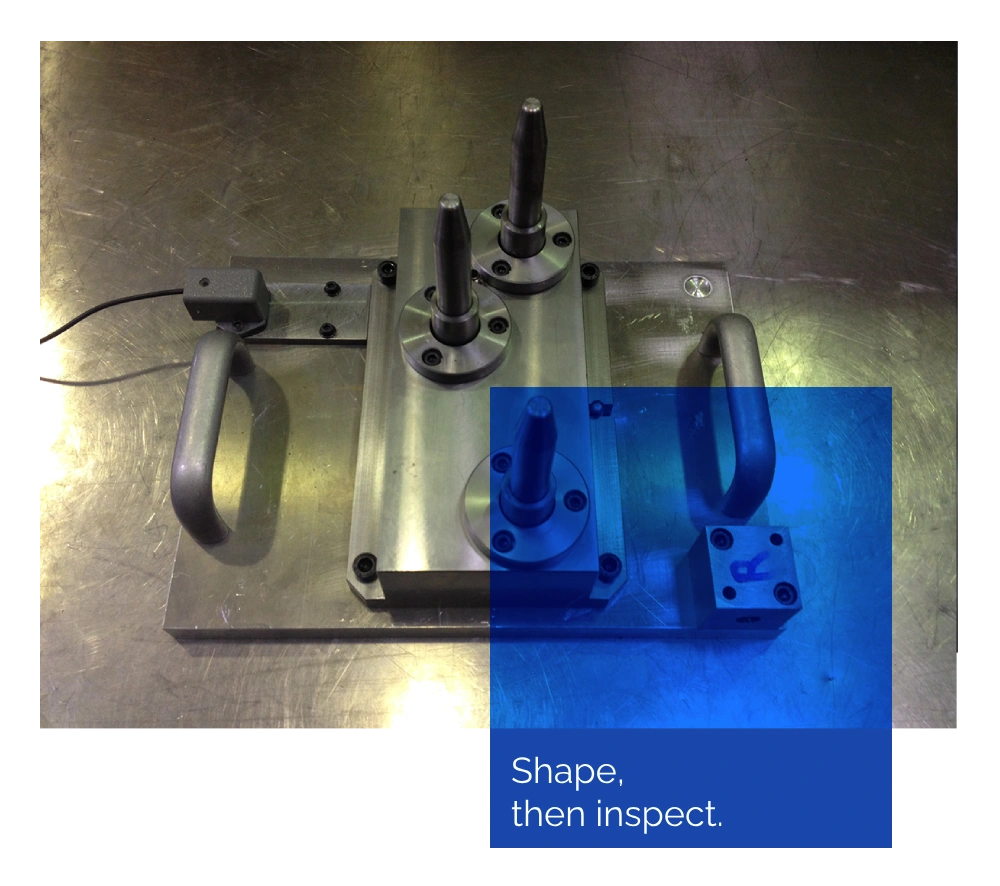

For more complex needs, we design technical jigs integrating multiple functions:

-

Mechanical or pneumatic clamping systems,

-

Integration of sensors or actuators,

-

Jigs combining assembly and inspection,

-

Ergonomic solutions for operator stations.

These jigs help partially automate operations while improving safety, repeatability, and efficiency.