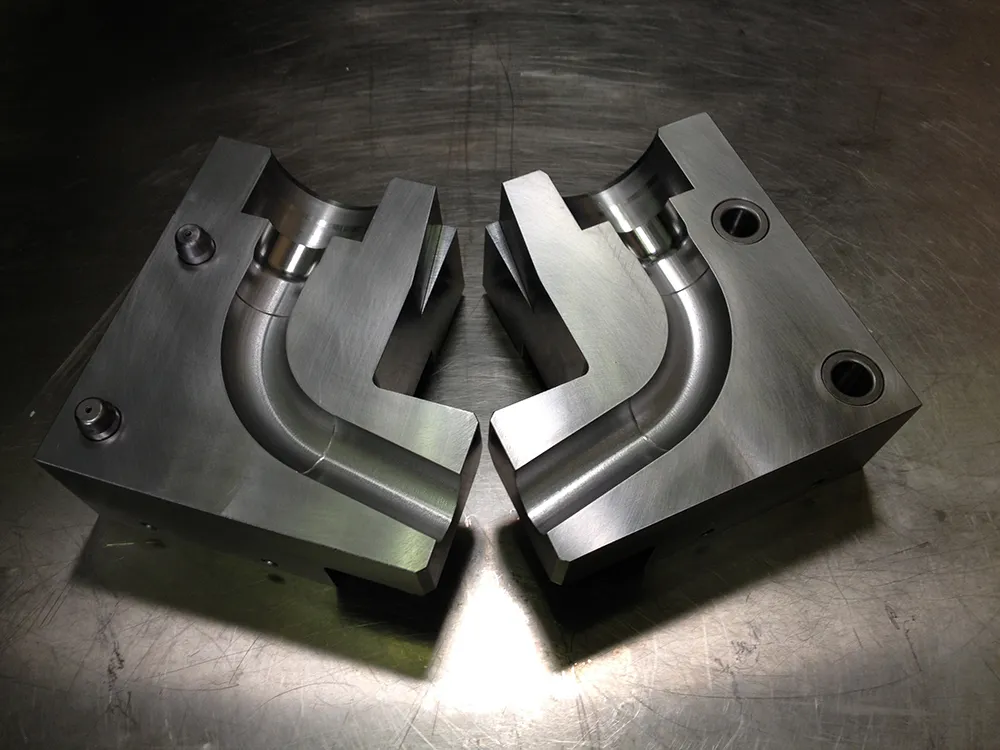

Bending and forming

tooling

For over 25 years, A3S Mécanique has been designing and machining high-precision bending and forming tooling for metalworking professionals.

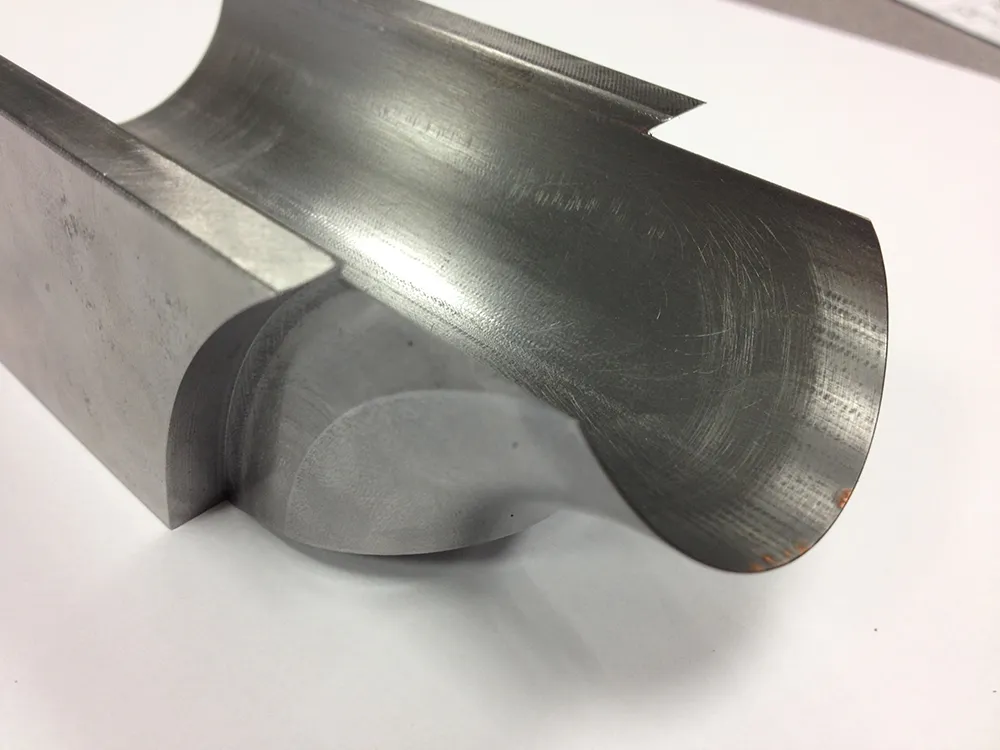

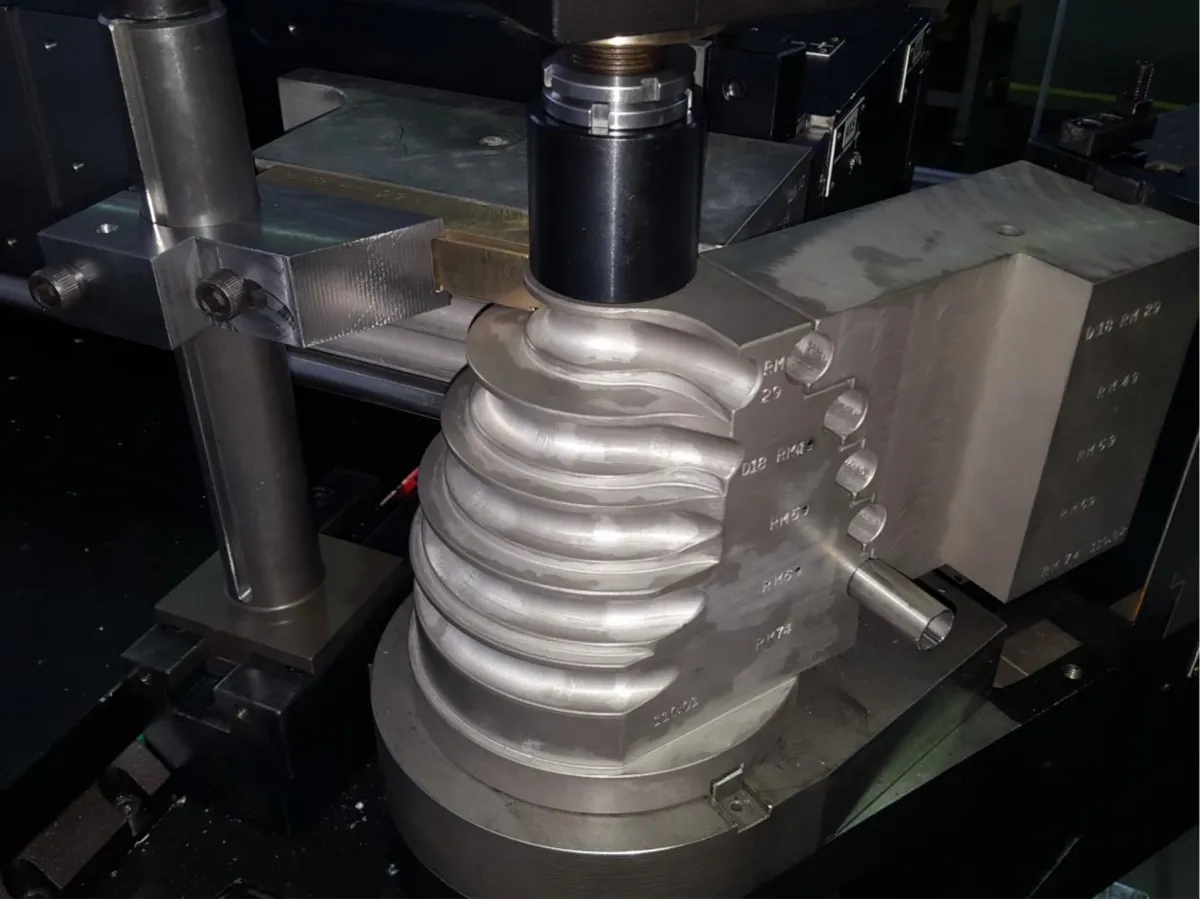

Based on a part drawing or a 3D file (.iges / .step), our design office can develop any type of tooling, even for complex geometries.

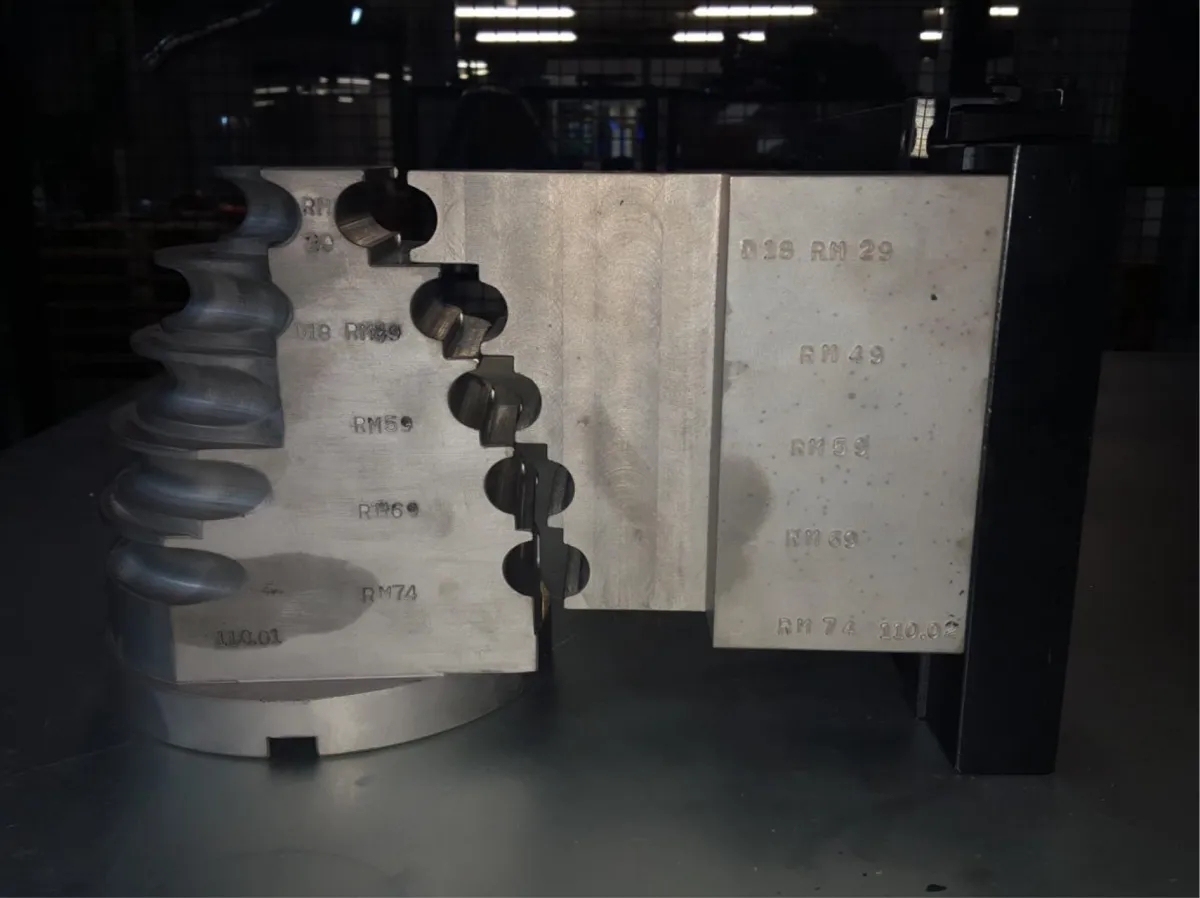

Single-stage or multi-stage tooling.

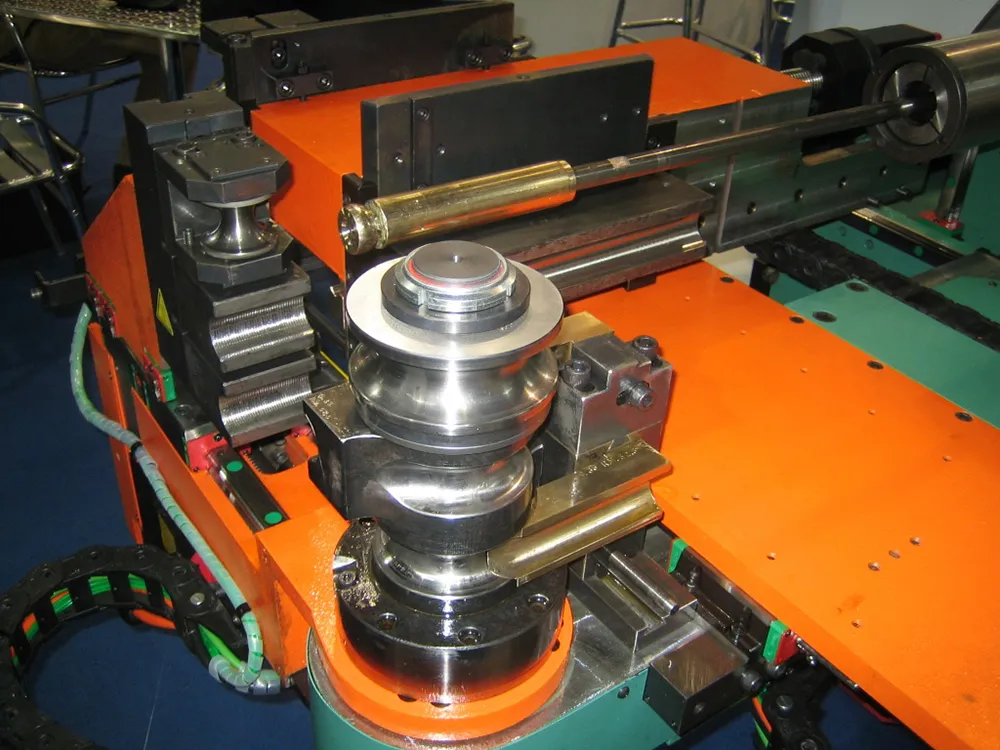

Left/right tooling, variable-radius, or mandrel-to-mandrel bending.

Configurations integrating machine modeling and specific clamping types.

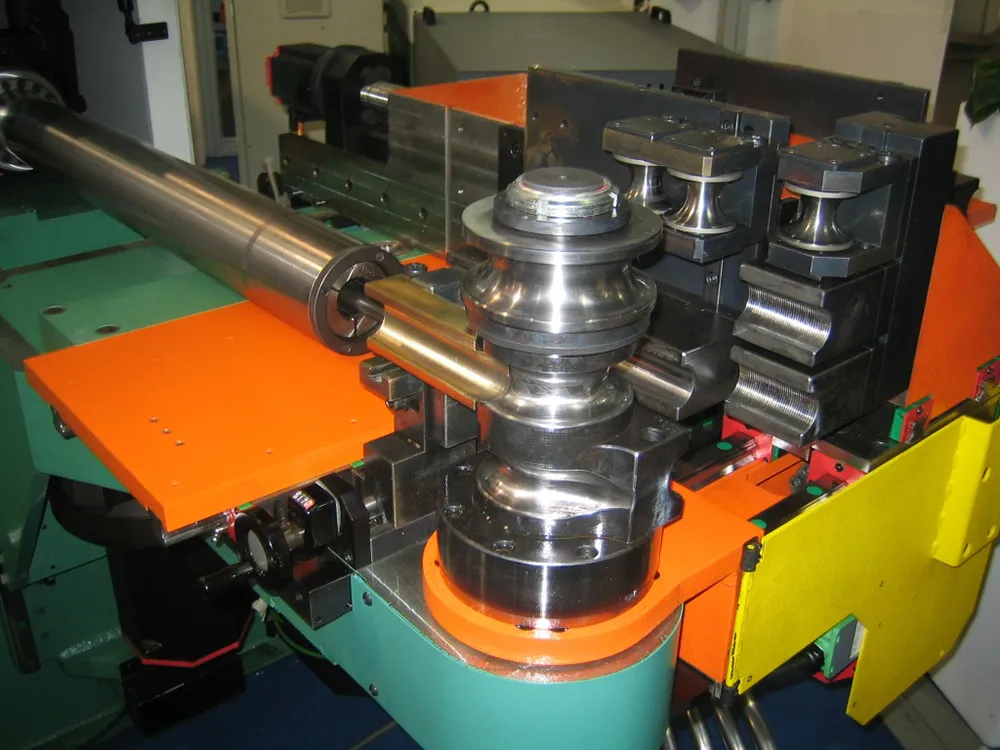

Each tool is custom-made to match the client’s machine.

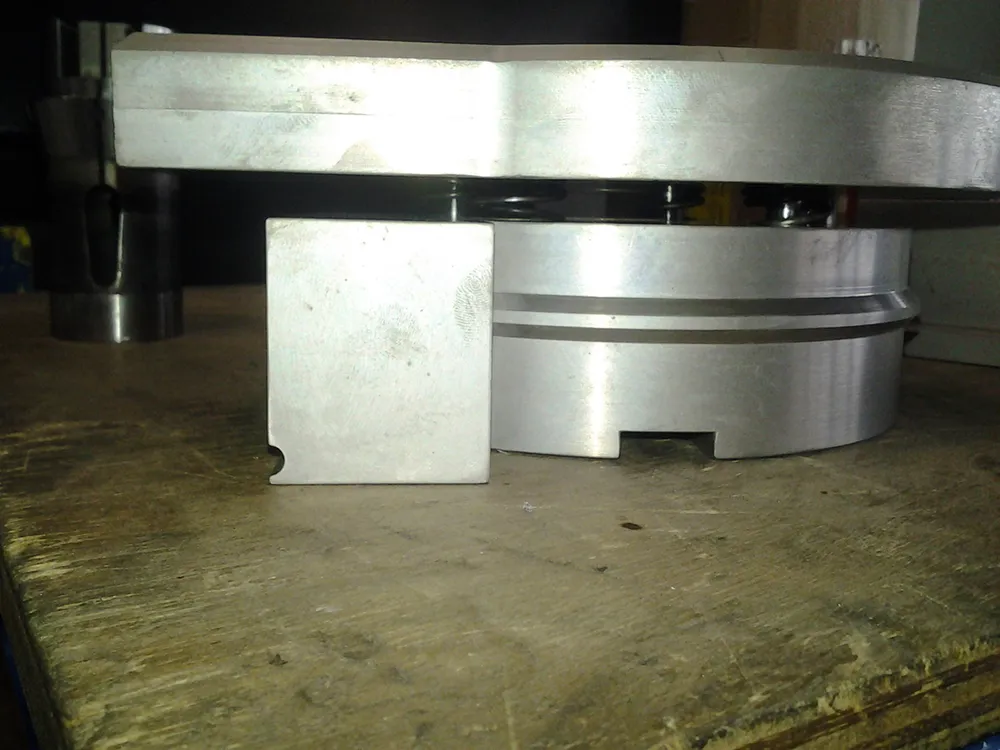

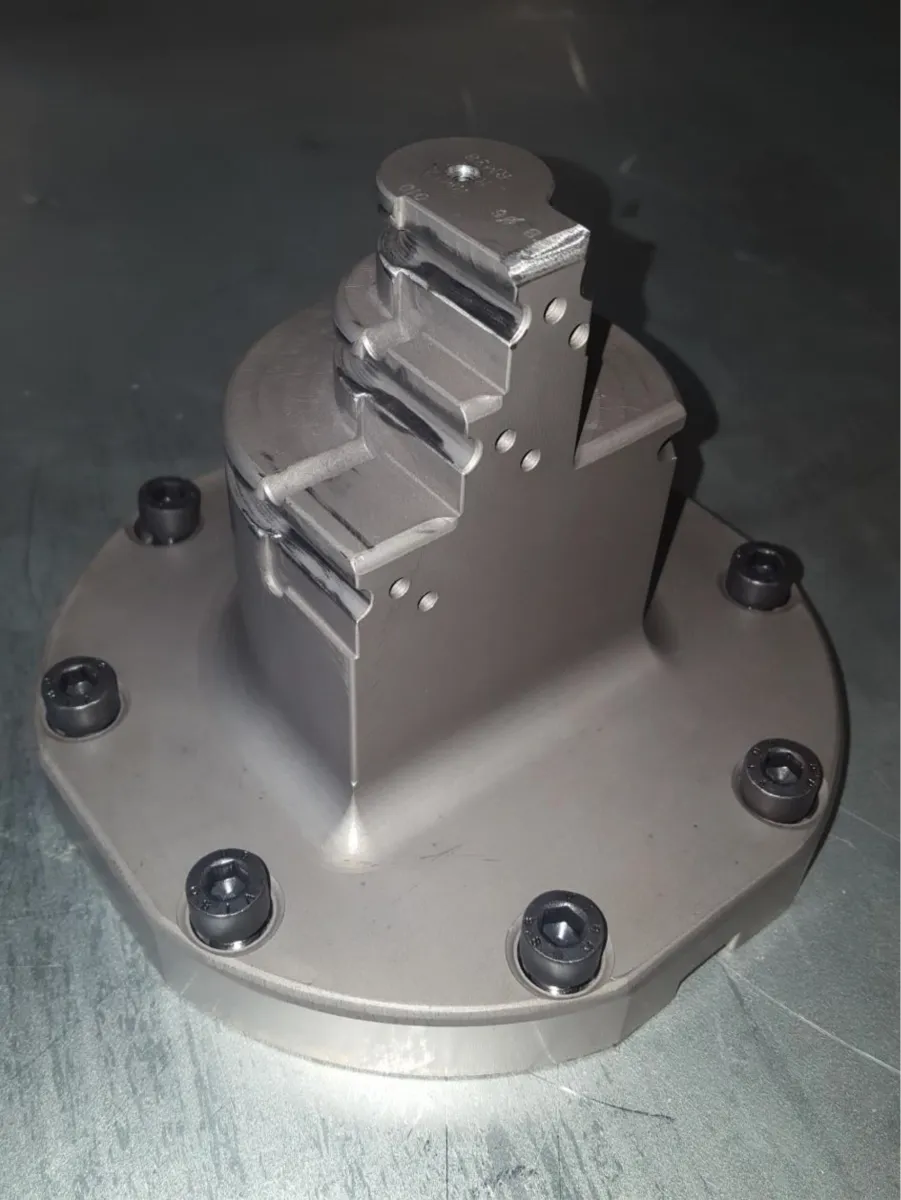

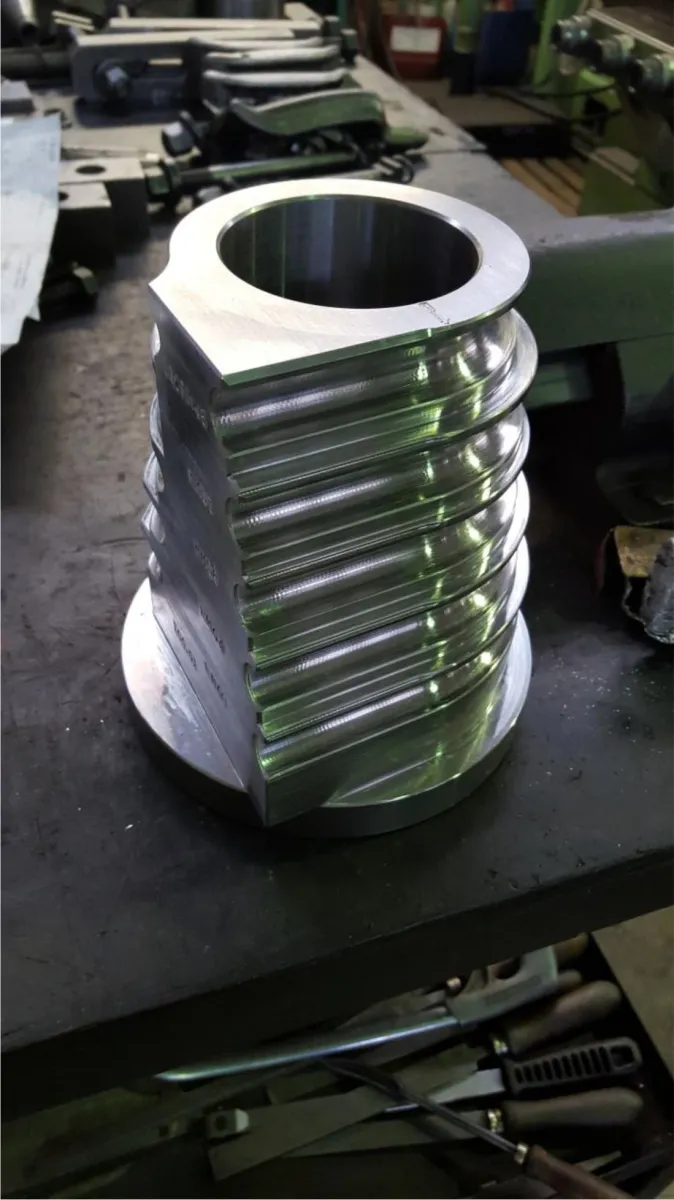

Thanks to a modern machine park, we machine all required components: die, jaws, slide, articulated mandrel, clamp, wrinkle-suppressor, etc

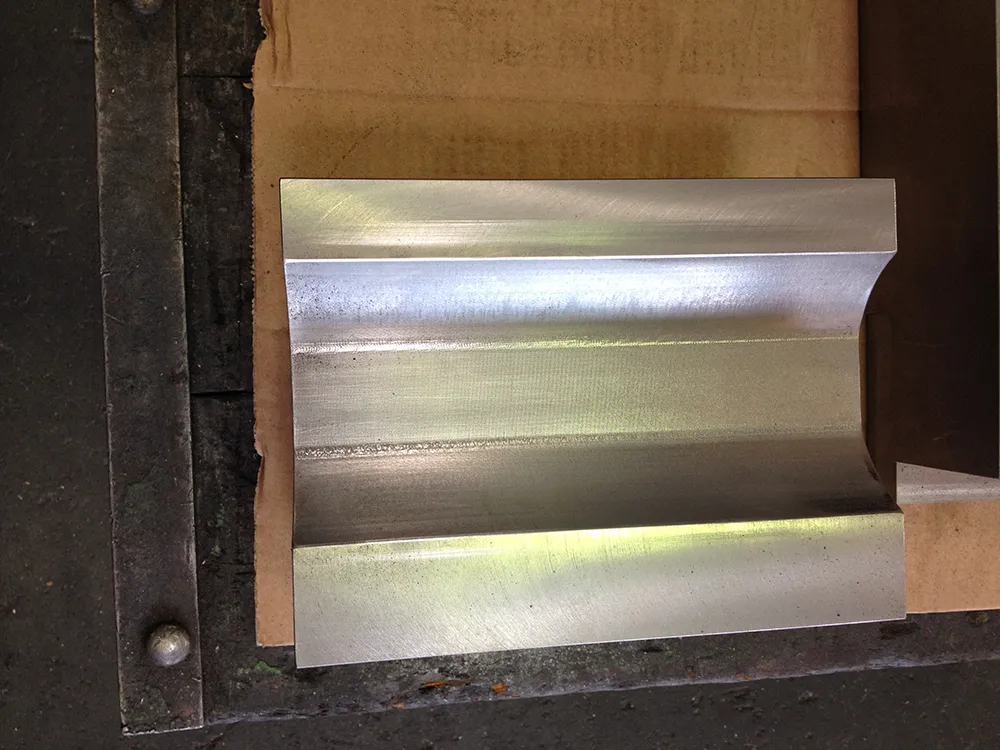

For round, square, rectangular tubes, MCR or special profile.

Compatible with steel, stainless steel, aluminum, copper, brass, etc.

We also manufacture forming tools: reduction, expansion, bulging, flaring, and other specific shapes.

- Maintenance and retrofit of bending and forming machines

- Tooling setup on machines similar to the client’s equipment

- Production of prototypes and pre-series of bent or formed parts

This integrated service allows us to validate the tooling in real conditions and ensure optimal performance from the very first use.