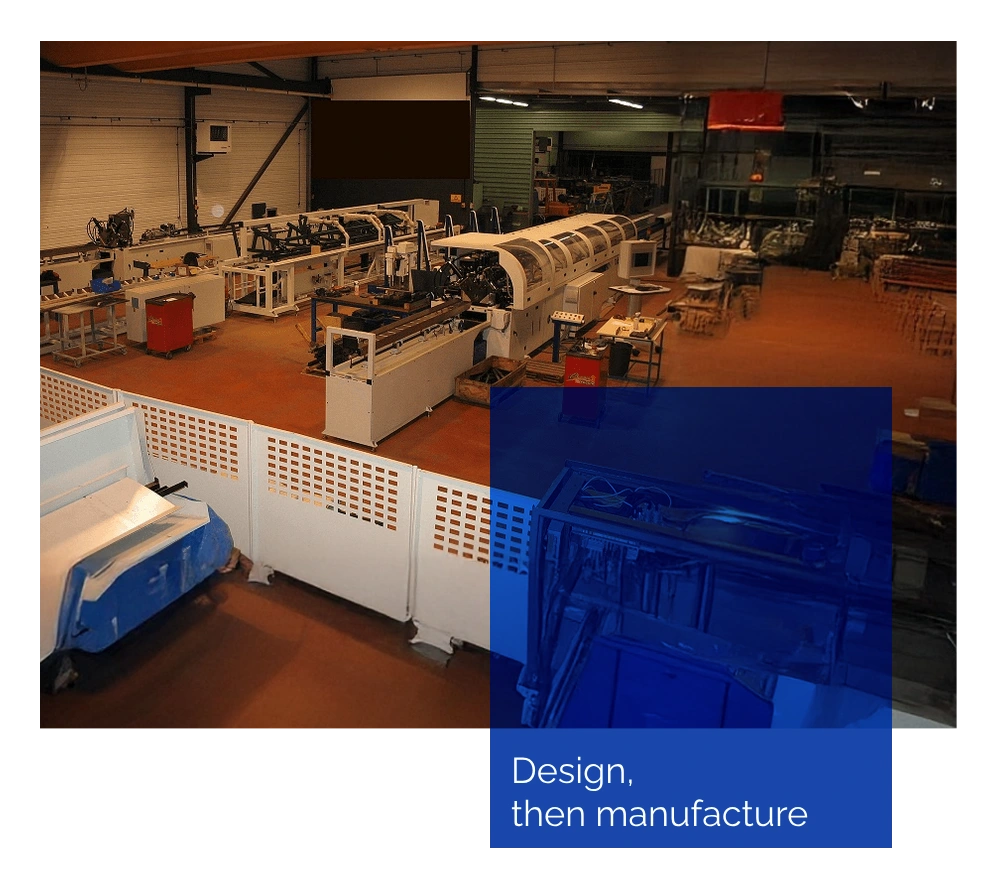

Custom design

of special-purpose machines

At A3S Mécanique, we design and manufacture custom industrial machines, aimed at automating, securing, or improving your production processes.

From needs analysis to commissioning, we support you at every stage of the project.

Our in-house design office works closely with our workshop to deliver complete, robust solutions tailored to your technical constraints, products, and production rates.

Our goal: to create reliable, high-performance, and safe machines, fully adapted to your applications.

Our design office creates robust and functional structures, tailored to your specific needs.

3D modeling, simulation, material selection: everything is designed for reliability, maintainability, and efficiency.

Key advantages:

-

Custom design

-

Mechanical optimization

-

Reduced maintenance constraints

We integrate modern automation systems: PLCs, touch interfaces, sensors, and supervision tools.

Each machine is easily operated, with maximum precision and safety.

Key advantages:

-

Simple and intuitive control

-

Customized automation

-

Industry 4.0 integration available

Our machines include all necessary systems to ensure operator safety and comply with current CE standards.

Protection, ergonomics, and documentation are considered from the design stage.

Key advantages:

-

CE compliance

-

Safety integrated from the design stage

-

Improved operator station ergonomics

Each of our machines is designed to be scalable and easy to maintain.

We also offer updates or future adaptations based on your needs.

Key advantages:

-

Simplified maintenance access

-

Extended lifespan

-

Guaranteed scalability

Case study: the Tube Center

to centralize tube bending, cutting, and forming

Client objective

Centralize multiple operations on metal tubes (bending, cutting, deburring, inspection) into a single compact, precise station suitable for varied production runs.

Our solution

A3S Mécanique designed and built a custom special-purpose machine called the Tube Center. It integrates several key functions into a single piece of equipment, with a touch interface, modular design, and high reliability.

Integrated functions

- Programmable multi-radius bending

- Automatic cutting and deburring

- End forming

- Integrated length and angle control

- Touchscreen control

- Adaptable to various materials (steel, stainless steel, aluminum, etc.)

Key strengths of the solution

- Time-saving: centralized operations

- Repeatability and quality guaranteed

- User-friendly thanks to automation

- Scalability: modular machine adaptable to other series

- 100% A3S-made: design, production, and fine-tuning in our workshops

Result

A compact, robust, and intuitive machine, perfectly integrated into the client’s production process, with a fast return on investment.