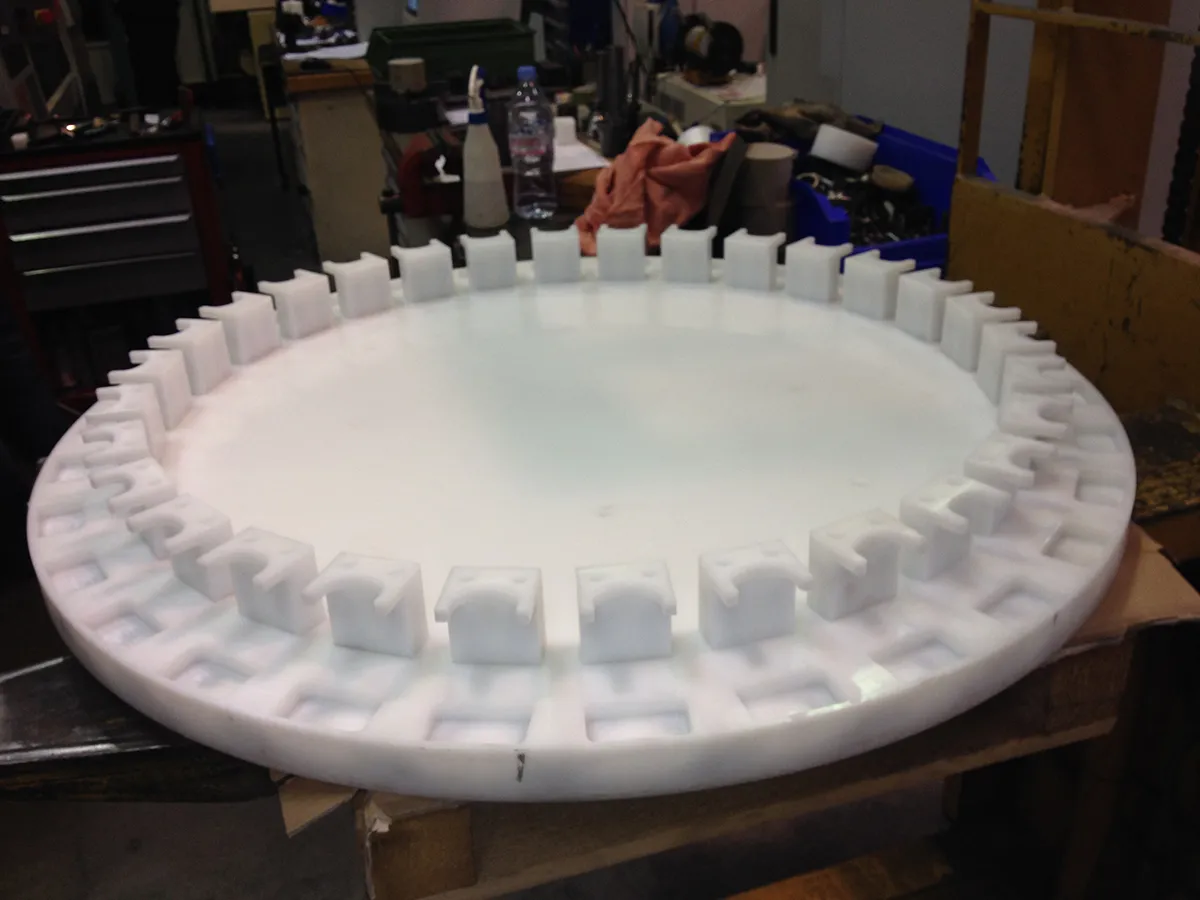

Machining of

mechanical parts

A3S Mécanique carries out metal part machining in small series or single units. Thanks to our workshop equipped with CNC machines, we produce parts in steel, stainless steel, aluminum, and other technical materials with a high level of precision.

Our services cover a wide range of processes, including turning, milling, electrical discharge machining, and many others, allowing us to work on various materials such as steel, aluminum, brass, stainless steel, or technical plastics.

Objective: to provide you with machined parts that conform to your plans and specifications, respecting deadlines and the strictest quality standards.

Turning is a material removal machining process, ideal for manufacturing cylindrical or conical parts.

At A3S Mécanique, we use numerical control lathes to perform operations such as turning, facing, threading, axial drilling, etc.

Advantages:

-

High dimensional precision

-

Excellent repeatability for series production

-

Adaptability to various materials

Applications: shafts, rings, axles, bushings, turned parts

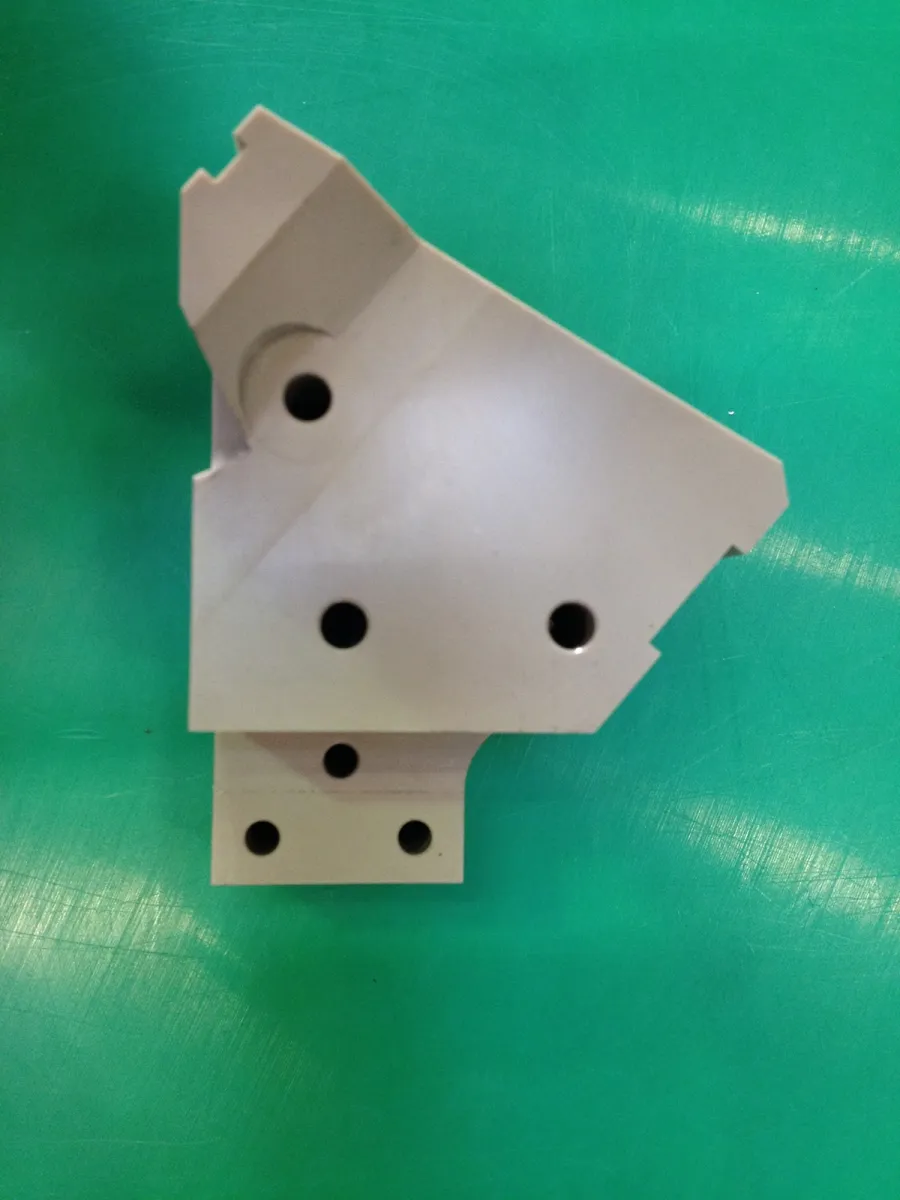

Milling enables the machining of flat surfaces, grooves, pockets, and complex shapes.

Our 3 to 5-axis CNC machining centers allow the production of parts with varied geometries and high precision.

Advantages:

-

Machining of complex shapes

-

High production flexibility

-

High-quality surface finish

Applications: housings, supports, plates, molds, prismatic parts

Electrical Discharge Machining (EDM) is a machining process using electrical discharges, ideal for hard materials or complex shapes.

We offer two types:

-

Wire EDM: for precise cutting of complex profiles

-

Sinker EDM: for cavities or specific internal shapes

Advantages:

-

Machining without mechanical stress

-

High precision on conductive materials

-

Creation of shapes impossible with conventional machining

Applications: tooling, dies, parts with complex internal shapes

We support our clients in the production of prototypes and small series by offering:

- A responsiveness for tight deadlines

- Technical support for part optimization

- A flexibility for adjustments during the project

Advantages:

- Rapid concept validation

- Reduced development costs

- Adaptability to changes in specifications

Applications: prototype parts, pre-series, design adjustments